Standing Strong Against Wind, Rain & Snow: Structural Integrity of ACM Panels

Protecting a building from Canada’s toughest weather starts with exterior cladding that holds its shape, seals out moisture, and resists impact.

Keep reading to learn how ACM panels withstand wind, rain, and snow thanks to rigorous testing, innovative construction, and engineered attachment systems.

Wind-Load Resistance

To prove a panel system can handle severe wind conditions, engineers use ASTM E330/E330M, a standardized test for structural performance under pressure:

- Procedure A captures load-deflection behaviour, helping designers understand how much panels can bend under force without failure.

- Procedure B focuses on pass/fail criteria and safety margins, including a required 10-second application of design wind load followed by 1.5x proof load testing to verify structural strength.

These standards are essential in cities like Calgary, where design wind pressures can range from 1.2 to 2.4 kPa depending on elevation and exposure.

Impact and Post-Impact Performance

ACM panels must also survive airborne debris and repeated pressure shifts during storms. ASTM E1886 tests simulate these conditions using missile impact and pressure cycling:

- This test confirms panels won’t detach or deform even after impact, followed by repeated loading and unloading, mimicking what happens during hurricanes or severe wind events.

- After impact, panels should still keep out water and air to protect the building from further damage.

Properly installed, certified ACM systems can withstand major storms without delaminating or detaching,

preserving safety and appearance.

Panel Construction and Core Bonding

Manufacturers test adhesive strength under thermal cycling and shear forces before bringing products to market. The strength of ACM panels starts from the inside with:

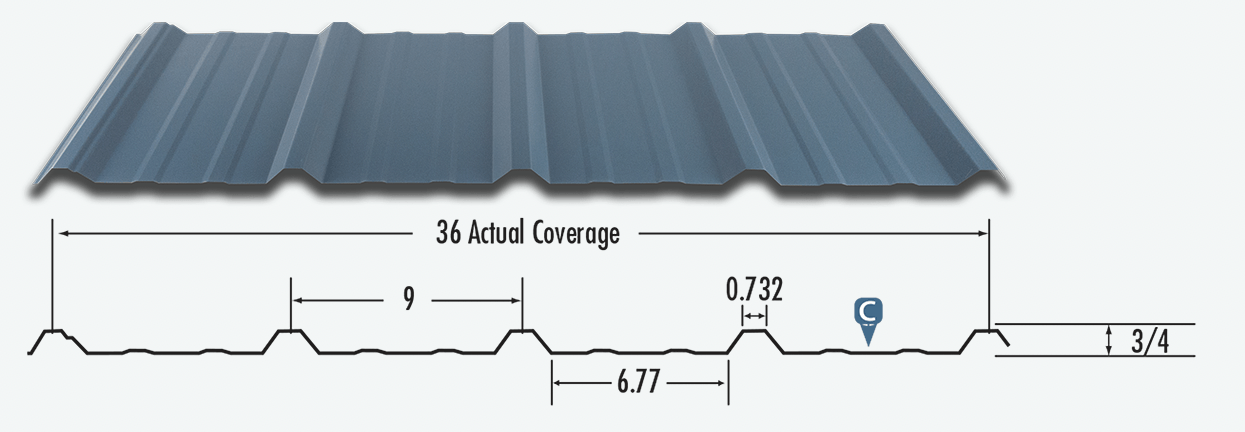

- Sandwich construction: Two pre-painted aluminum sheets bonded to a polyethylene or fire-retardant core create a rigid and lightweight panel

- Bonding adhesives: Distribute loads evenly and resist long-term stress. A high-quality bond prevents delamination during freeze–thaw cycles and holds strong under heavy snow accumulation or rapid temperature changes.

Attachment Systems and Sub-Girts

Even the strongest panel won’t hold without the proper support behind it. Rain screen and dry-joint designs rely on gaskets, splines, and vents to manage water movement and promote drainage behind the cladding.

These systems also help balance air pressure, limiting how much water gets forced in during wind-driven rain. Beneath the surface, metal sub-girts (usually 16–22 gauge galvanized steel) spread structural loads evenly. Many come pre-punched to speed up installation and improve on-site alignment.

Testing and Compliance Standards

Before any panel system gets the green light, it must go through rigorous testing to prove it can withstand pressure and stand the test of time.

ASTM E331 tests the system’s resistance to water penetration under static pressure, while AAMA 507 and 508 ensure proper pressure equalization and drainage for rain-screen assemblies.

On the material level, tests like ASTM D3039, which measure tensile strength, and other composite standards assess how each layer contributes to the panel’s

overall durability.

Tested Strength, Trusted Performance

Your material choices determine a building's ability to withstand harsh weather. Without trusted, proven systems, you risk potential damage, costly repairs, and even safety concerns.

Phoenix Metals provides ACM systems that we thoroughly test for strength, resilience, and

long-term value, helping ensure your building remains strong, no matter what nature brings.

To learn more or request a quote,

Contact Us Today.