The Role of Sub-Girts in Metal Cladding Systems: Design, Installation, and Thermal Performance

Every high-performing cladding system starts with what you don’t see. Panels may get the attention, but the hidden framework behind them — the sub-girts — determines how well the system lasts, drains, and insulates. Skip the details here, and you’ll end up with costly callbacks.

Keep reading to learn why sub-girts matter for design, installation, and thermal performance in today’s Calgary cladding systems.

What Are Sub-Girts?

Sub-girts are secondary framing members that sit horizontally or vertically between the primary building structure and the exterior cladding. They act as a support grid, anchoring panels while creating a cavity for drainage, airflow, and insulation.

Design Considerations for Sub-Girts

Placement, spacing, and compatibility with panel systems all impact how the wall performs and its appearance once finished.

Placement and Spacing

The spacing of sub-girts depends on the panel size, wind load, and the building's use. Too close together, and you over-engineer the wall. Too far apart, and panels can bow or oil-can. Engineers typically set sub-girts on 16″, 24″, or 32″ centres, depending on the metal wall panels used and the performance goals.

Compatibility With Panel Systems

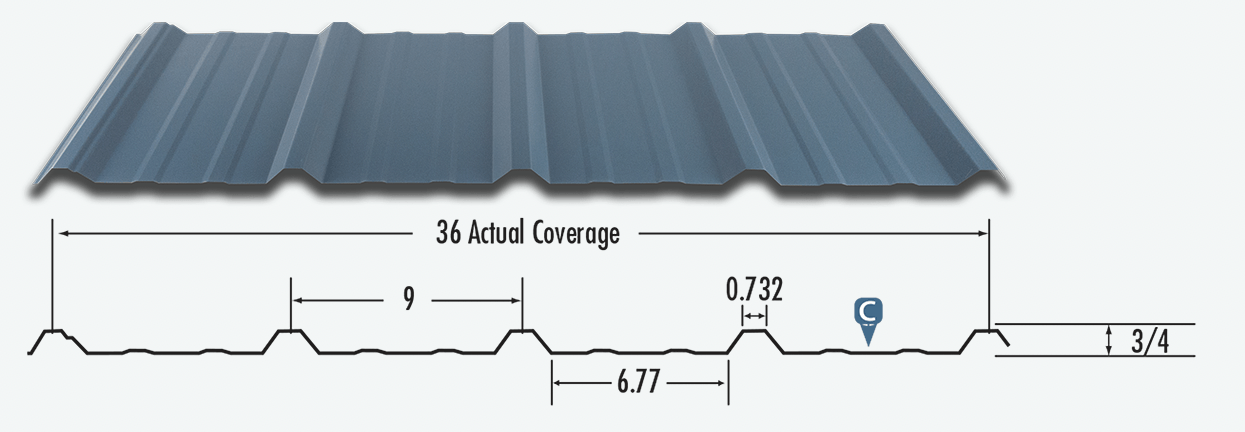

Corrugated panels, standing seam, and concealed-fastener systems all have different attachment requirements. Matching the proper sub-girt depth and alignment to the chosen panel is non-negotiable.

Installation Best Practices

Design only goes so far — sub-girts need to be installed correctly to do their job.

Creating Drainage Cavities

Water always finds a way in. The role of sub-girts is to make sure it also finds a way out. Proper installation creates drainage cavities that allow moisture to escape, protecting the integrity of the cladding and the structure behind it.

Ensuring Secure Panel Attachment

Sub-girts provide the fastening surface for cladding panels. Installers must line them precisely to keep panels square and secure. Misaligned sub-girts cause gaps, rattling panels, and compromised weatherproofing.

Integration With Insulation Layers

Energy codes in Alberta demand more from building envelopes. Sub-girts must integrate with insulation layers without crushing or displacing them. Proper detailing prevents gaps that leak heat and raise operating costs.

Thermal Performance Benefits

By reducing thermal bridging and enhancing envelope performance, sub-girts enable buildings to meet modern energy standards while lowering their long-term operating costs.

Reducing Thermal Bridging

One of the biggest enemies of energy efficiency is thermal bridging, which is when heat slips through the framing instead of staying inside. Sub-girt systems, designed with thermal clips or stand-offs, reduce direct metal-to-metal contact, cutting down on heat transfer.

Improving Building Envelope Efficiency

By creating consistent insulation layers, minimizing air leakage, and supporting ventilated rainscreens, sub-girts elevate the efficiency of the entire envelope. For metal cladding in Calgary, where the weather swings from freezing winters to hot summers, this efficiency directly translates to comfort and cost savings.

Build It Right With Phoenix Metals

The success of any cladding project depends on the unseen framework that makes them work. Sub-girts may not be flashy, but they’re one of the most important design choices you’ll make.

At

Phoenix Metals, we bring decades of experience in metal wall panels and cladding systems in Calgary. From engineering sub-girt layouts to installing panels that stand the test of time, we make sure every detail works together.